Contents

- 1 Fireproof wood material COOL WOOD

- 2 Fireproof wood structure technology

- 3 Examination and specifications for a 2-hour fireproof structural member

- 4 First certification for 3-hour fireproof resistance in Japan

- 5 New “round pillar” design of wood fireproof material

- 6 Nanyo-City Cultural Center — Japan’s largest wooden fireproof hall — featuring COOL WOOD structural members that Shelter developed and patented

Fireproof wood material COOL WOOD

The fireproof structural wood member developed and patented by our company covers the wood in the core with gypsum board; the gypsum board is subsequently covered with an extra layer of wood. Production of COOL WOOD is straightforward and it has a low cost. In addition, the appearance of the wood can give the buildings a feeling of the warmth of trees. At the time of combustion, the water vapor emitted by the gypsum board exerts a fire extinguishing effect and therefore prevents the fire from reaching the core of the structural wood member.

The material is relatively easy to process and can be manufactured with various types of wood according to the design and cost. The wood appearance of columns and beams imparts a warm feeling to the building’s finish.

◎One-hour fireproof structural specifications (columns, beams, outside walls)

◎Two-hour fireproof structural specifications (columns, beams, partition walls, outside walls, floors)

◎Three-hour fireproof structural specifications (columns, beams)

Patents acquired in Japan, Canada, and Switzerland. Minister of Land, Infrastructure, Transport and Tourism (Japan) certified.

【Features】

・All tree species can be chosen for the surface layer

・JAS materials, incombustible, quasi-incombustible, flame-retardant treated lumber can also be used

・Easy to process (can be manufactured in easily obtainable materials and special tools are unnecessary)

・Solid wood and laminated lumber is also available

・A feeling of woodiness

Fireproof wood structure technology

【Three-layer structure】

(Patent No. 4359275)

1.The internal load bearing section is wood

2.The intermediary fire stoppage layer is gypsum board

3.The surface material is wood (columns, beams)

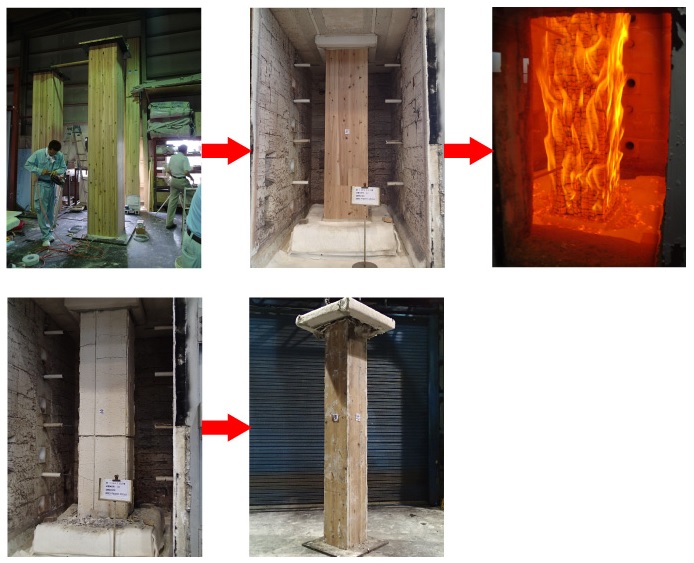

Examination and specifications for a 2-hour fireproof structural member

In this test, the fireproof structural wood member was exposed to fire for over 2 hours. The maximum heating temperature exceeded 1000℃. After a 2-hour lapse time, and even after the completion of the artificial heating, the test member was placed for an extra 6 hours in a fully closed furnace. After a total of 8 hours, the furnace was opened, and the test wood member was peeled off the coating, the remaining bark was removed, and it was confirmed that it showed no signs of brown spots.

This test was intended to demonstrate that even in the situation that firefighters cannot combat the fire for a long time, the structural integrity of the wood member remains intact. This test exposed the fireproof structural wood member to intense heat for 2 hours, and the goals and implications of this test were to ensure that the structural integrity of the wood member remains intact until the fire is extinguished.

First certification for 3-hour fireproof resistance in Japan

Shelter was the first in Japan to obtain the certification of the Minister of Land, Infrastructure, Transport and Tourism for three hours of fire resistance, in December 2017. High-rise wooden buildings are being built all over the world, and the wooden buildings constructed in Japan were only allowed up to 14 stories high (2-hour fireproof specifications). With the realization of the 3-hour fireproof specification, which is the longest legal fireproof time, there is no limit on the number of floors. Indeed it will be pragmatic to incorporate wooden structures into skyscrapers of 15 stories or more that have been built with steel frames and reinforced concrete structures. Such designs will be entirely possible.

We will continue to develop further technologies toward the realization of a “fire-resistant, humane- and globally eco-friendly wooden city” with a wide variety of wooden buildings in urban areas.

.png)

New “round pillar” design of wood fireproof material

Our COOL WOOD know-how can be used to create “round pillars” that feature both high fire resistance and imaginative designs.

Moreover, we make it possible to apply the aesthetically pleasing artistic concepts of entasis (a gentle bulging bodice) and fluting (vertical grooves on the surface). Because such elegant concepts demand complicated processing and extreme accuracy they can only be fabricated using our 3D processing machine technology. Designers and creative clients can request most any artistic design — such as polygons and imaginatively curved surfaces — and they can be realized with extreme accuracy.

Nanyo-City Cultural Center — Japan’s largest wooden fireproof hall — featuring COOL WOOD structural members that Shelter developed and patented

- The first large-scale fireproof wooden-construction hall in Japan

- Accommodates as many as 1,403 performance attendees

- Features locally-grown cedar

- Encompasses 3 stories above ground and a single level below

- Total floor area measures 5,900㎡

- Use of laminated lumber totals 3,570㎥

- Use of log material totals 12,413㎥

- Opened for performances in October 2015